Since starting my Master’s in Supply Chain Management, I’ve realised how much I misunderstood the field.

I used to think it was just about trucks on highways, boxes in warehouses, forklifts moving pallets, and maybe some Excel sheets tracking inventory. To me, SCM looked like a world of barcoded, clipboards, cold storage units, and some manager signing off the papers. Some background operation. Something technical. Something physical. Something … not for me.

So, naturally, I was in for a surprise. That image started to crack.

I began to see that;

- It’s not just movement. It’s movement with meaning.

- It’s not just a storage thing. It’s strategy in motion.

- It’s not just operations. It’s orchestration.

Now, I know. Supply chain is about power (who controls the flow, and how it shifts business decisions), visibility (knowing what’s happening, where, and why it matters), strategy (aligning sourcing, planning, delivery and customer value), and value creation (not just reducing costs, but creating impact).

In my head, it’s no longer about what’s visible on the surface. It’s about the invisible architecture underneath every brand, every store shelf, every order confirmation email

If you’re someone — like I was — coming from a marketing or business background, you might think SCM is all mechanics. But it’s actually a mindset. A system of cause and effect. A game of what-if and what-next.

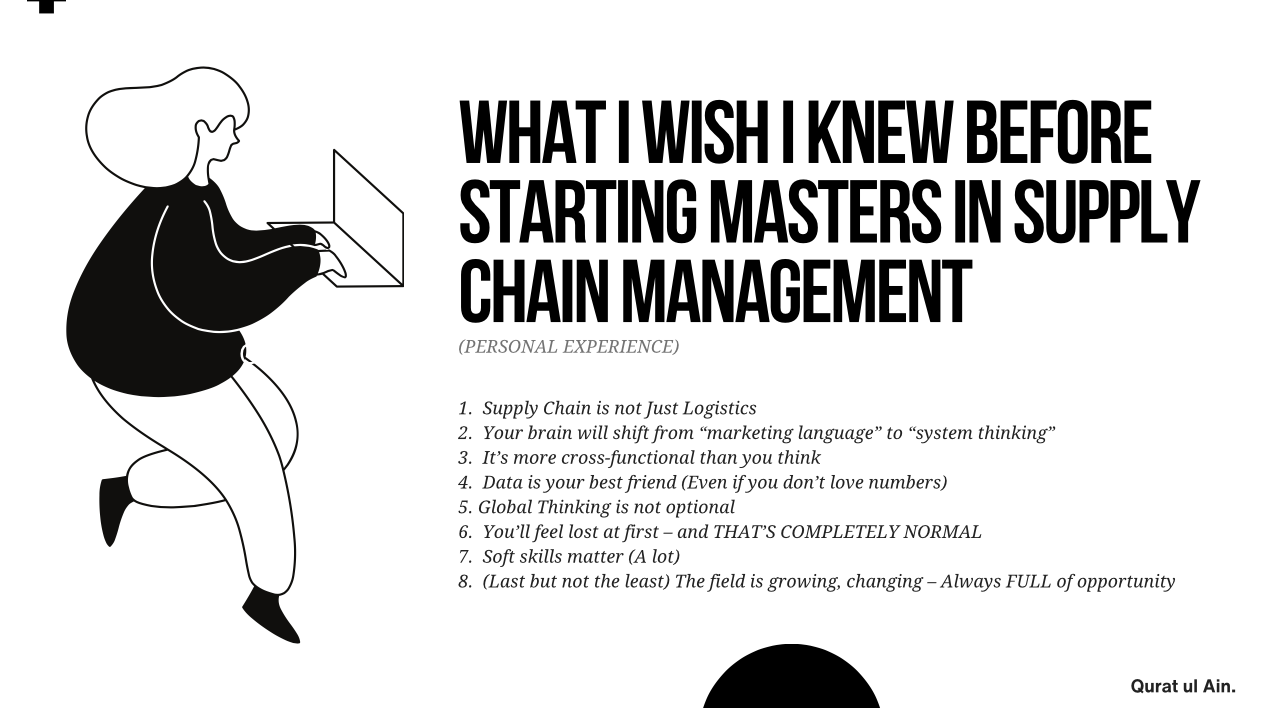

This post is everything I wish I knew when I first stepped into this world.

1. Supply Chain is not Just Logistics

At first, I thought logistics was the supply chain. But logistics is just one piece — movement.

Supply chain? That’s the master plan behind everything.

You need to think beyond ports and pallets. You need to read between the lines. You need to think inside the air.

Start thinking like a system builder, not just a delivery manager.

Ask: How do all these pieces fit together? What can I add value? What happens If one part breaks down.

2. Your brain will shift from “marketing language” to “system thinking”

I was used to buyer personas and brand tones. Now I think in lead times. I think in inventory buffers. I think in supplier scorecards.

Here’s how it changed me;

- “How to I sell better?” → “How do I deliver better”

- “What does customer want?” → “How do I make sure they get it – on time, in full sustainably?”

Start reading about Systems Thinking early. It’s the lens that helps everything start to make sense.

3. It’s more cross-functional than you think

One of the biggest surprises for me? You don’t just “stay in your lane” in supply chain.

You end up working with operations, IT, HR, Highway authorities, Economics, even marketing. And not just once in a while, but regularly.

Here’s what it looks like in practice:

- Procurement can’t move forward without sign-off from finance.

- Distribution needs support from IT to track and optimise deliveries.

- Decisions around inventory can directly affect customer satisfaction (and yes – even those big promises made by the marketing team!)

It’s like you’re the link that quietly keeps all these departments in sync — not in the spotlight, but absolutely essential behind the scenes.

Tip: Learn to translate. Speak a little “finance,” a little “tech,” a little “ops.” SCM works best when everyone’s aligned — and you might be the one holding it all together.

4. Data is your best friend (Even if you don’t love numbers)

SCM is powered by dashboards, KPIs, Excel, ERPs, and forecasts.

I’LL BE HONEST.

I wasn’t a “numbers” person. The thought of dashboards and forecasts used to feel… well, intimidating.

But don’t worry. You don’t need to be a data scientist. You need to be data-aware.

It means;

- Understand what you’re looking at (e.g., is this a trend? a red flag? a pattern?)

- Know why that number matters — what does it impact down the line?

- Learn how to ask better questions — because good supply chain decisions come from interpreting data, not just collecting it.

Once you get comfortable with it, you’ll start noticing how every small number tells a bigger story — about performance, about customer experience, or even about what’s coming next.

And that’s when the numbers stop being scary — and start becoming your edge.

5. Global Thinking is not optional.

When I first heard about “global supply chains,” I thought it only applied to companies like Amazon or Apple. But the truth is — even small, local businesses rely on global movement.

Maybe the raw materials come from abroad. Maybe the packaging is imported. Maybe the product is made locally but shipped internationally.

You quickly realize that no supply chain exists in isolation.

Divide things into;

- Trade routes – and how a blocked canal can ripple across the world.

- Port delays – that can stall your product launch.

- INCOTERMS – the rules that define who’s responsible for what during shipping.

- Geopolitics – how a policy shift or conflict affects sourcing strategies

- Supplier risks – especially when you’re working across borders and time zones.

And suddenly, headlines start looking different.

- A port strike in Karachi isn’t just news, it’s a disruption.

- A policy change in China? That might delay your entire production cycle.

- Fluctuations in the USD-PKR exchange rate impact your procurement costs.

- Shipping container shortages or freight rate hikes after global disruptions (like the Suez Canal blockage or Red Sea tensions) affect how affordable it is to move your product.

- Customs clearance delays due to regulation changes or political instability can stall e-commerce orders, especially for businesses relying on cross-border drop shipping.

- Oil price volatility affects transportation costs for local trucking as well as international freight — and that ripples through the entire supply chain

It’s like your thinking zooms out — from city-level to continent-level. And that shift changes how you approach every decision after.

You become someone watching the map, not just the factory floor.

6. You’ll feel lost at first – and THAT’S COMPLETELY NORMAL

Let me be real with you.

In my first few classes, I felt completely out of place. I came from a marketing background, and suddenly I was hearing terms like EOQ models capacity planning, highways, Spain, Dubai, frameworks like they were everyday language.

Meanwhile, I was still trying to remember what lead time actually meant.

But here’s what I’ve learned since then: feeling lost doesn’t mean you don’t belong. It just means you’re learning something new.

What helped me most was realising that everyone brings their own lens to the field;

- Engineers are great at thinking in systems and solving technical problems.

- Marketers understand customer needs.

- Finance folks thing in terms of cost and trade-offs.

- Economics step from inflation.

- And others bring experience from retail, healthcare, IT and it all fits in somewhere.

I started noticing how my background gave me a different kind of insight. Where others saw just stock levels, I saw customer expectations. Where others tracked delivery time, I thought about brand trust.

That’s when it clicked.

I didn’t need to compete with everyone else’s strengths — I just needed to own mine.

You’ll get there too. You don’t have to know it all on day one — and honestly, no one does.

7. Soft skills matter (A lot)

You will negotiate.

You will manage suppliers.

You will present to leadership.

You will handle crises.

Whatever I explained above isn’t the whole story.

What no one really tells you upfront is this: You’ll spend just as much time talking to people as you do analyzing data.

So while you’re learning the tools and techniques, don’t forget to build the soft side too:

Diplomacy. Communication. Problem-solving. Resilience.

Because supply chain isn’t just about moving things. It’s about managing people, priorities, pressure, world — all at once.

And sometimes, your most important job will be explaining something incredibly complex in a way that makes sense in one sentence. Like why a shipping delay in China is suddenly upsetting customers in Lahore.

That’s the real skill and it’s what makes you stand out.

8. (Last but not the least) The field is growing, changing – Always FULL of opportunity

You’re here because you really care about your thought-shift.

Supply Chain Management. You’re not joining a traditional field. You’re joining a fast-evolving force.

You’ll hear buzzwords like;

- Circular supply chain

- Last-mile delivery

- Demand sensing

- Green logistics

- Digital twins

Tip: Stay curious. Subscribe to newsletters, follow LinkedIn experts, watch TEDx talks on the future of supply chains.

THE BEST PART?

There’s space for all kinds of people. Whether you’re analytical, tech-focused, sustainability-driven, or just love solving puzzles — there’s room for you here.

Don’t try to master everything. Find what excites you.

→ Love strategy? Go for SC planning

→ Like people? Try procurement or supplier management

→ Like numbers? Dive into forecasting or analytics

→ Care about the planet? Study sustainable supply chains

Know this: Supply Chain is not just a job. It’s a mindset.

It’s about connecting everything that a business is behind the scenes. Once you understand it, you’ll never look at a product or business the same way again.

Leave a Reply