Just four things:

Source. Make. Move. Sell.

That’s it!

If you strip down every business in the world, you’ll find it’s doing one (or all) of these things – finding materials, making products, moving them, or selling them.

And the system that connects all these activities together – smoothly, efficiently, and strategically – is called Supply Chain.

When this entire system is planned, organized, led, and controlled from the point of origin (like a farm, factory, supplier) to the point-of-consumption (the customer’s hands), we call it Supply Chain Management.

When done right, it’s invisible.

When it fails, the world notices.

What exactly is Supply Chain Management?

When I first heard the term Supply Chain, I thought it was something mechanical, like an actual chain made of suppliers. But no. It’s more like a living network. People, data, trucks, containers, factories, and yes, sometimes chaos. All moving in sync. It’s the reason your new phone arrived in 2 days, or your favourite chips disappeared from store shelves for weeks.

According to Encyclopaedia Britannica, Inc. Supply Chain Management is defined as;

The process of managing the flow of resources, activities, and people involved in the development of a product from the production or sourcing of raw materials to the sales and delivery of the final product.

In simpler words — it’s everything that happens from the idea of a product to the moment it lands in your hands.

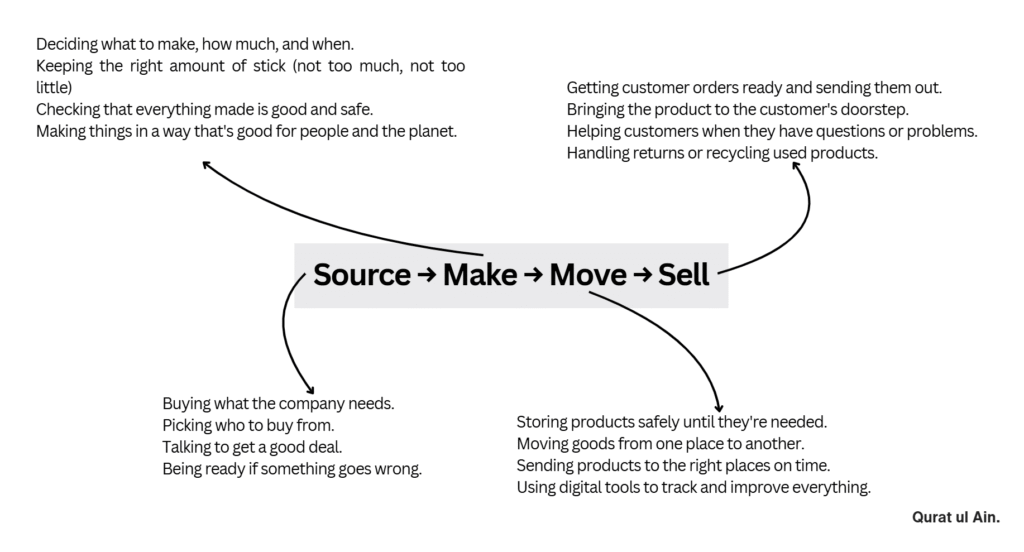

The four building blocks of Supply Chain

They’re simple, but they hold the entire foundation of how businesses work.

Let’s break it down into the four basic actions every business does:

1. Source (Finding what you need to start)

Every journey starts with sourcing.

Before a company can make anything, it needs materials or components.

Sourcing Is the Top Strategic Priority for 35% of Procurement Departments. This statistic comes from the 5th edition of PwC’s Digital Procurement Survey.

But “sourcing” is just buying stuff, it is about choosing the right partners and getting fair deals. What it includes is;

- Buying what the company needs.

- Picking who to buy from.

- Talking to get a good deal.

- Being ready if something goes wrong.

For example, if you’re running a tea brand in Pakistan, sourcing means finding high-quality tea leaves from farms in Shinkiari or Sri Lanka and packaging materials from Lahore.

Each of these is a small link but together they make your business possible.

2. Make (Turning materials into products)

This is where raw materials turn into something valuable.

The “make” phase is where value is created through manufacturing, assembling, or processing.

What it includes:

- Deciding what to make, how much, and when.

- Keeping the right amount of stick (not too much, not too little)

- Checking that everything made is good and safe.

- Making things in a way that’s good for people and the planet.

For example;

Your tea leaves now go through cleaning, blending, flavouring, and packaging, in bulk or in small sachets – before they’re ready for sale.

3. Move (Getting products where they need to go)

Once your product is made, it needs to move. From factory floor to the customer’s door.

This stage is the engine room of logistics.

Every truck, ship, train, and plane that moves goods across the world is a part of this network.

What it includes:

- Storing products safely until they’re needed.

- Moving goods from one place to another.

- Sending products to the right places on time.

- Using digital tools to track and improve everything.

For example;

Your packages tea boxes are stores in a warehouse in Rawalpindi, shipped via truck to Karachi and then sent by sea to Dubai for export.

Even a single delay — say, due to port congestion — can cause ripple effects across the chain.

Logistics costs can account for up to 30% of total delivery costs and Transportation costs account for nearly 58% of total logistics expenses. (Source)

That’s why efficiency here directly impacts the company’s profitability.

4. Sell (Delivering the final product to the customer)

And finally, the last part. Sell.

This is where all your efforts meet the customer.

What it includes:

- Getting customer orders ready and sending them out.

- Bringing the product to the customer’s doorstep.

- Helping customers when they have questions or problems.

- Handling returns or recycling used products.

For example;

A customer orders your tea online. It’s picked from the warehouse, shipped via a courier, and delivered to their doorstep within 48 hours.

That single smooth experience builds brand loyalty — and that’s the ultimate goal.

The Supply Chain Never Sleeps

The supply chain doesn’t end once the product is sold.

Customer feedback, product returns, and even recycling data loop back into the system — helping companies improve the next round of sourcing, making, and moving.

That’s why modern supply chains aren’t linear anymore. They’re circular, digital, and data-driven.

Even Amazon’s recommendation system uses what you buy to predict what they’ll need to stock next — that’s supply chain intelligence in action.

Why Supply Chain Management Matters So Much

Because it shapes everything.

From cost to customer experience.

From speed to sustainability.

SCM keeps the world moving.

A strong supply chain means:

- Lower costs and less waste

- Faster, more reliable deliveries

- Happier, loyal customers

- Stronger supplier partnerships

- More resilience in global disruptions

During COVID-19, we saw what happens when supply chains break — empty shelves, delayed deliveries, and rising prices.

That’s how essential SCM is: when it fails, the world feels it.

A Simple Way to Remember SCM

Whenever you get confused, just remember this one line:

“Supply Chain Management connects everything a business does — from where it starts to where it ends.”

It’s about connection, coordination, and continuous improvement.

Supply Chain Note

“Behind every product you use, there’s a world of planning, people, and precision — and that’s the beauty of supply chain management.”

Leave a Reply